Across global industrial communities, discussions around f...

READ MORECATEGORIES

Residential Gas Valve Manufacturer

-

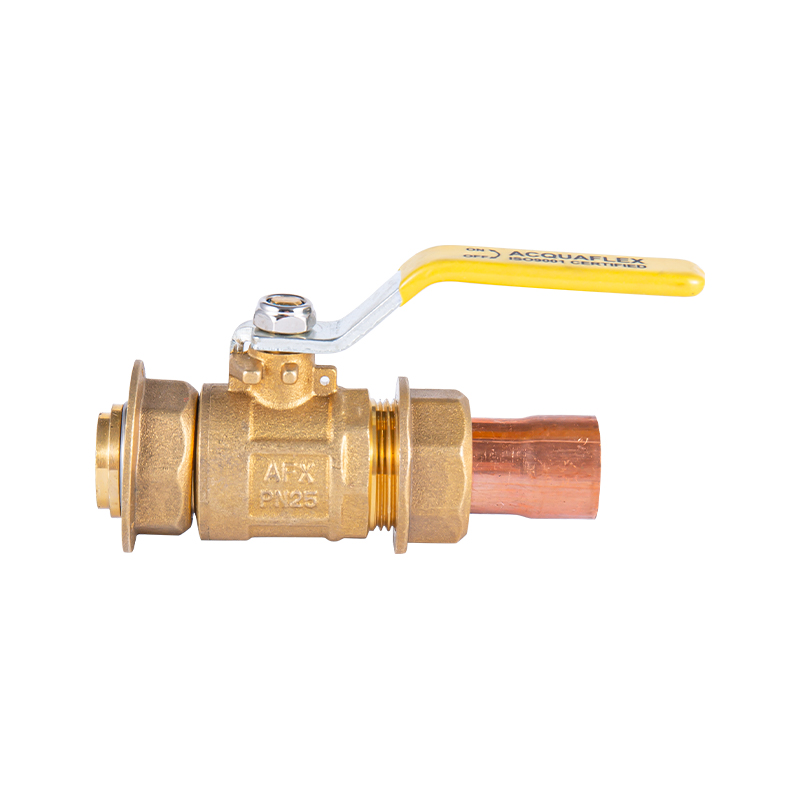

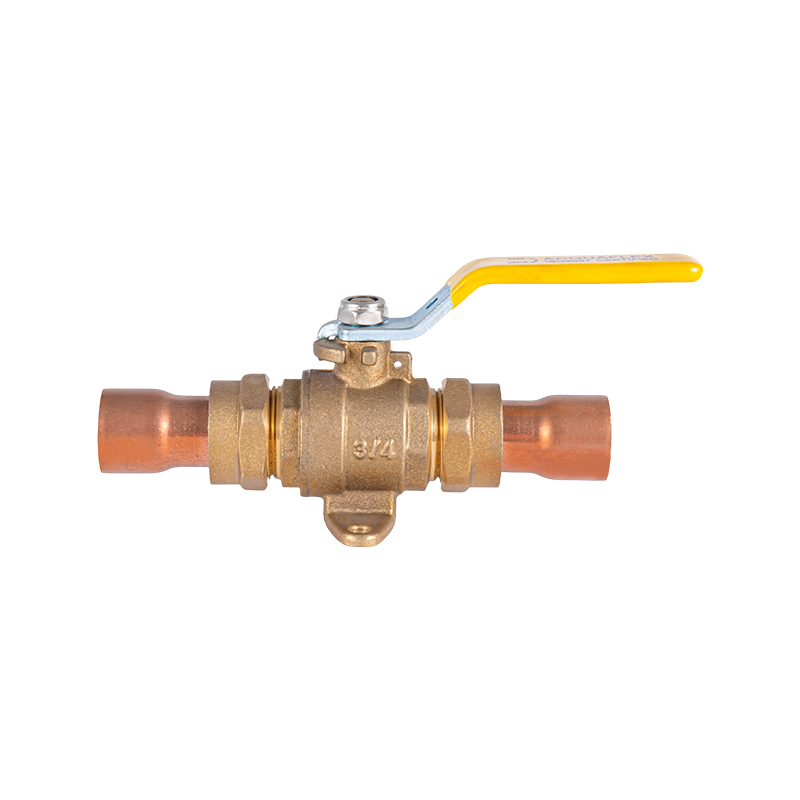

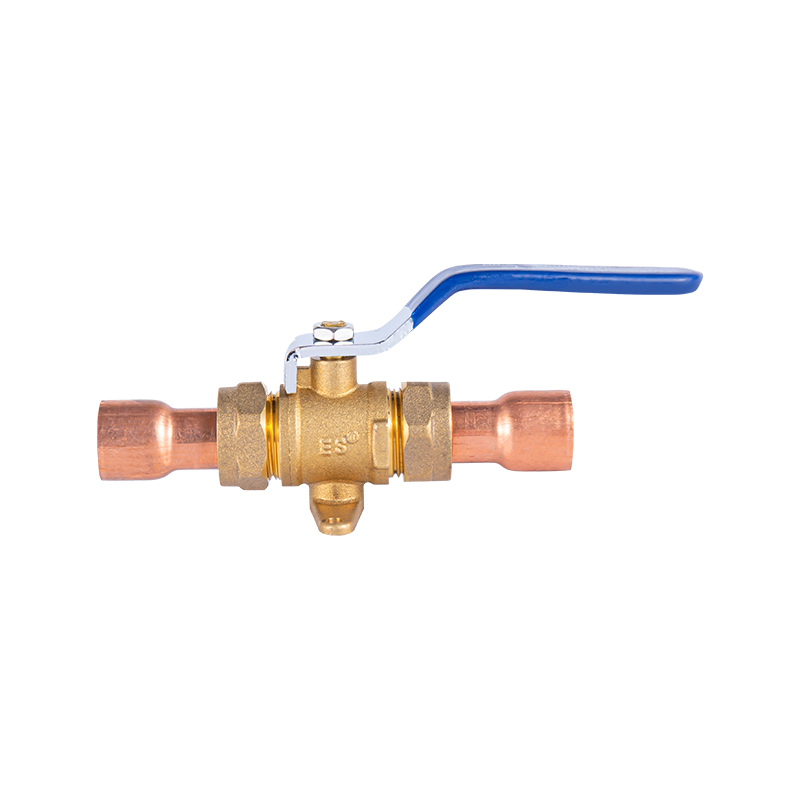

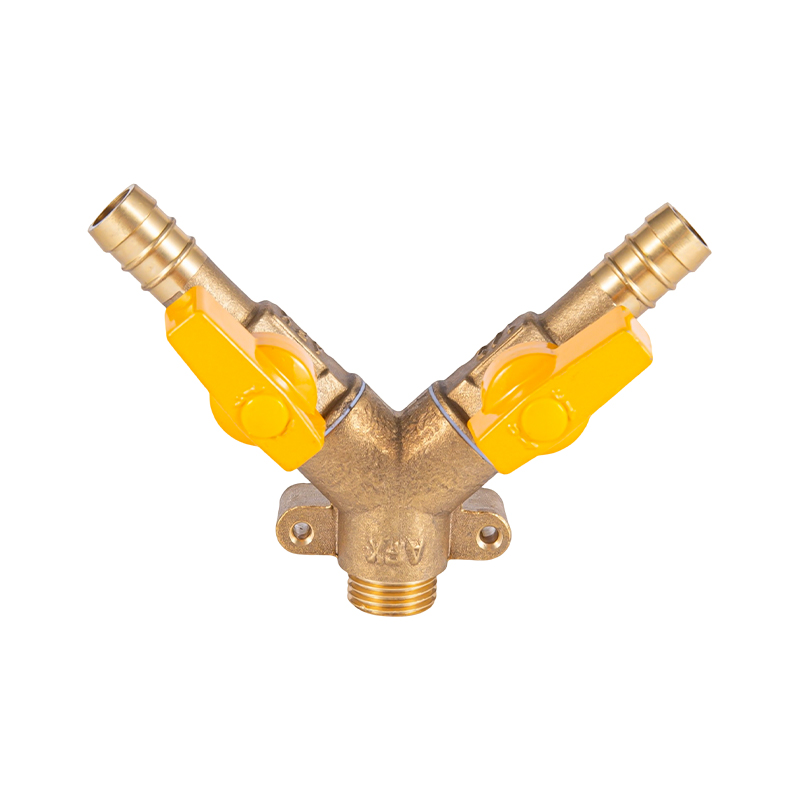

XY-3001 Brass Gas Valves

1/2"×14mm 1/2"×16mm

-

XY-3002 Brass Gas Valves

1/2"×14mm 1/2"×16mm

-

XY-3003 Brass Gas Valves

1/2"×14mm 2/1"×16mm

-

XY-3004 Brass Gas Valves

7/8"×22mm

-

XY-3005 Brass Gas Valves

3/4" 1" 11/4"

-

XY-3006 Brass Gas Valves

3/4" 1"

-

XY-3007 Brass Gas Valves

1/2"

-

XY-3008 Brass Gas Valves

1/2"

-

XY-3009 Brass Gas Valves

1/2"

-

XY-3010 Brass Gas Valves

1/2"

-

XY-3011 Brass Gas Valves

1/2"

-

XY-3012 Brass Gas Valves

1/2"

Our household brass gas valve has a nominal pressure of 1.6 MPa.

Working medium: water, non-corrosive liquid, saturated vapor

Working temperature: -10 ℃ ≤ t ≤ 120 ℃ Specification: 1/2" to 4", pipe thread meets ISO228 standard.

The surface of the product can be natural color, nickel-plated, or chrome-plated, and the valve body can be made of different copper materials, such as HPB57-3, CW617, CW617N, C3700, etc. The other parts can be made of copper, iron, stainless steel, or zinc alloy, fully meeting the needs of all market customers for products at different price points.

Brass gas valves are a key component in gas control systems used across residential, commercial, and industrial environments. These valves are designed to manage the flow of gases such as natural gas, propane, and other non-corrosive gases, providing control, isolation, or shut-off functionality within gas pipelines or appliances.

Constructed primarily from brass, these valves offer stable mechanical performance and are suitable for gas-related applications due to brass's resistance to corrosion and chemical reactions with fuel gases. The material also ensures reliable sealing and durability in both indoor and outdoor settings under appropriate conditions.

Brass gas valves serve as crucial components in gas systems, bridging the gap between gas sources and a variety of appliances like stoves, heaters, ovens, water heaters, and industrial burners. Their essential function is to enable the secure activation or deactivation of gas flow, catering to the needs of installation, maintenance, and emergency response.

This diverse category encompasses several valve styles, each tailored to distinct flow control needs. Ball valves, for instance, are popular for their straightforward quarter-turn operation that swiftly modulates the gas flow. In contrast, needle valves excel in providing fine-tuned control, particularly in scenarios with low pressure demands.

These valves come in a spectrum of sizes and are equipped with various connection standards, such as threaded, compression, or flared fittings, to accommodate a broad array of gas system setups. The selection of the connection method is often influenced by national plumbing regulations, specific installation demands, and the characteristics of the gas line in use.

The design of brass gas valves may incorporate T-handles, lever handles, or round knobs, aligning with their intended application and setting. Some models boast enhanced safety features, including locking mechanisms and seals that minimize the risk of leakage under normal operating conditions.

The installation of brass gas valves must be entrusted to qualified professionals to uphold stringent safety protocols and comply with local regulations. Routine inspections and maintenance are also essential to identify any signs of wear, leaks, or mechanical malfunctions.

This product category offers a comprehensive selection to fulfill a variety of gas flow control requirements. Each product listing is accompanied by pertinent specifications, such as size, pressure rating, connection type, and material composition, to facilitate an informed selection process.

The company is adjacent to the seaport city of Wenzhou Airport in the south, Jiaojiao, Taizhou and Wenzhou Expressways in the west. It is an hour and a half away from Wenzhou and Taizhou Airports, and the transportation is extremely convenient. The company mainly produces copper ball valves, copper globe valves, copper check valves, copper pressure reducing valves, temperature control valves, angle valves and other copper valve products with complete specifications and guaranteed quality. In the fiercely competitive market economy environment, Xianyun Valve adheres to the development concept of "quality determines strength", adheres to the business policy of "people-oriented, honesty as the criterion", insists on relying on technological innovation, constantly absorbs advanced experience at home and abroad, and comprehensively promotes advanced Yun Valve has transformed from a traditional enterprise to a high-tech industry.

The company now has advanced production and testing equipment and can independently design, develop and produce hundreds of products. The company pays special attention to brand image, constantly develops new products and improves product quality, and develops the market with the best products. "Excellent quality, customer satisfaction" is the company's eternal pursuit. The company will be guided by market demand, continue to innovate, and wholeheartedly provide users with high-quality products and perfect after-sales services.

The company pays attention to the training of talents, strives to build a "first luck spirit" of hard work, unity and hard work, and strives to build a "strength enterprise".

English

English 中文简体

中文简体 русский

русский Email us now!

Email us now!