Are Smarter Flow Control Choices Redefining Modern Piping Systems?

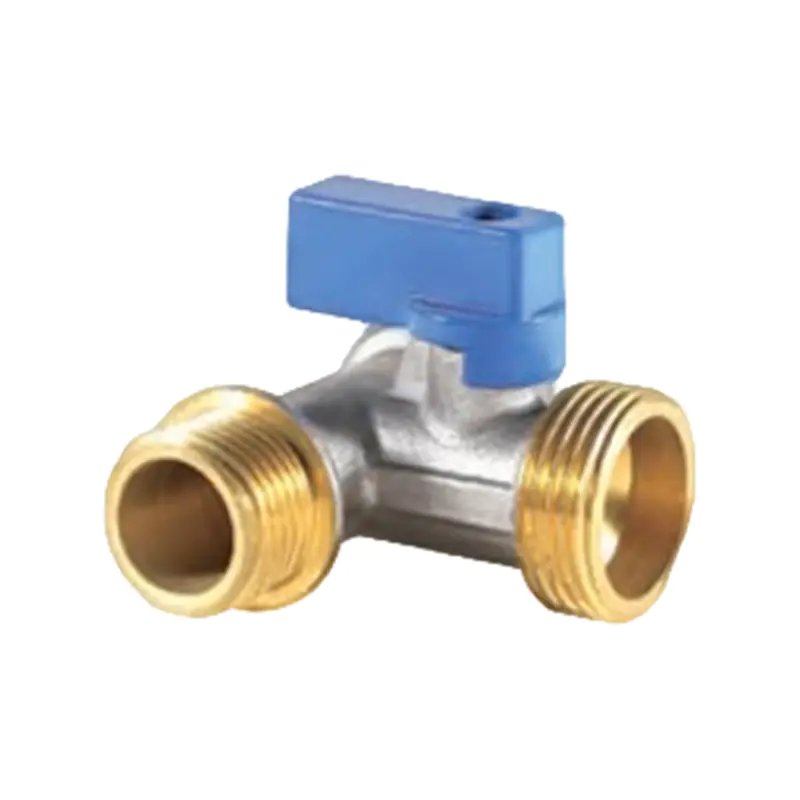

Across global industrial communities, discussions around flow control are becoming more practical and experience-driven. Engineers, maintenance managers, and procurement teams are no longer satisfied with components that simply meet baseline specifications. Instead, they focus on how equipment behaves after months or years of operation. In many overseas technical forums and social platforms, the Y-type Ball Valve is frequently mentioned as a response to common frustrations around flow resistance, inspection difficulty, and system instability.

Real-World Maintenance Concerns Are Driving Change

One of the lots of discussed pain points in international markets is maintenance efficiency. Users often share experiences of valves that perform well initially but become difficult to manage over time due to internal buildup or awkward installation angles. These challenges directly affect routine inspections and increase the likelihood of unexpected shutdowns.

Y-type configurations are increasingly appreciated because their flow path feels more intuitive in daily operation. Many engineers note that smoother internal transitions make it easier to keep systems running cleanly without increasing inspection frequency. This aligns well with the current preference for designs that reduce long-term workload rather than adding hidden complexity.

Protecting Systems Before Problems Spread

Another recurring topic on overseas social media is contamination control. Rather than reacting after debris has damaged pumps or instruments, users are looking for ways to stop issues at an earlier stage. This is where the concept behind a Check Valve with Screen naturally fits current expectations.

Instead of adding separate filtration devices, many system designers prefer integrated protection that works quietly in the background. A screened check valve supports this mindset by helping prevent reverse flow while also intercepting unwanted particles. The appeal lies not in advanced terminology, but in the sense that the system is “looking out for itself” during daily operation.

Application Scenarios That Influence Buying Decisions

Modern buyers rarely choose valves based on catalog descriptions alone. They want to see how components respond in familiar situations, such as:

- Water and utility pipelines where sediment accumulation is a constant concern

- Industrial circulation systems that must maintain directional flow under changing pressure

- Process lines where stability matters more than frequent manual adjustment

In these scenarios, Y-type designs are often associated with steadier flow behavior, while screened check valves are valued for quietly protecting downstream components. The combination addresses multiple operational worries without forcing users to redesign their pipelines or retrain maintenance teams.

From Individual Components to System Thinking

A noticeable shift in overseas markets is the move toward system-level thinking. Buyers increasingly ask how each valve affects the overall pipeline rather than judging parts in isolation. Topics such as cumulative pressure loss, inspection coordination, and component compatibility appear frequently in professional discussions.

Valves that integrate easily into existing layouts tend to receive more attention. Y-type structures are often favored because they align naturally with angled piping sections, while check valves with screens are appreciated for adding protection without demanding extra installation space. This “fit-first” mentality reflects a desire to improve performance without disrupting established workflows.

Reliability Without Changing User Habits

One concern repeatedly raised online is whether improved performance requires new habits. Products that force users to change tools, routines, or inspection logic often face hesitation. Practical flow control solutions succeed when they feel familiar from day one.

Well-designed valves support existing maintenance practices rather than replacing them. When operation feels predictable and servicing steps remain straightforward, users are more likely to trust the equipment and recommend it within their professional networks.

Practical Performance Builds Long-Term Confidence

From a manufacturing perspective, credibility in overseas markets comes from understanding daily operational realities. Users value suppliers who design with real conditions in mind—pressure fluctuations, debris exposure, and limited maintenance windows. Clear design intent and consistent performance matter more than promotional language.

As industries worldwide continue refining their approach to pipeline efficiency and protection, interest is shifting toward solutions that quietly solve common problems. By aligning with how systems are actually used, flow control setups incorporating the Y-type Ball Valve ,Check Valve with Screen are increasingly viewed as reliable, practical choices for modern industrial applications.

-

Feedback

English

English 中文简体

中文简体 русский

русский Email us now!

Email us now!