In industrial piping systems around the world, selecting t...

READ MORECATEGORIES

Regulating Ball Valve For Sale

-

XY-1001 Brass Ball Valves

1/2" 3/4 1" 11/4" 11/2" 2"

-

XY-1002 Brass Ball Valves

1/2" 3/4" 1" 11/4" 11/2" 2"

-

XY-1003 Brass Ball Valves

1/2" 3/4" 1" 11/4" 11/2" 2"

-

XY-1004 Brass Ball Valves

1/2" 3/4" 1" 11/4" 11/2" 2

-

XY-1005 Brass Ball Valves

1/2" 3/4" 1" 11/4" 11/2" 2" 3" 4

-

XY-1006 Brass Ball Valves

1/2" 3/4" 1" 11/4" 11/2" 2"

-

XY-1007 Brass Ball Valves

16x16 20x20

-

XY-1008 Brass Ball Valves

1/2" 3/4" 1" 11/4" 11/2"

-

XY-1009 Brass Ball Valves

1/2" 3/4"

-

XY-1010 Brass Ball Valves

1/2" 3/4" 1"

-

XY-1011 Brass Ball Valves

1/2" 3/4" 1"

-

XY-1012 Brass Ball Valves

1/2" 3/4"

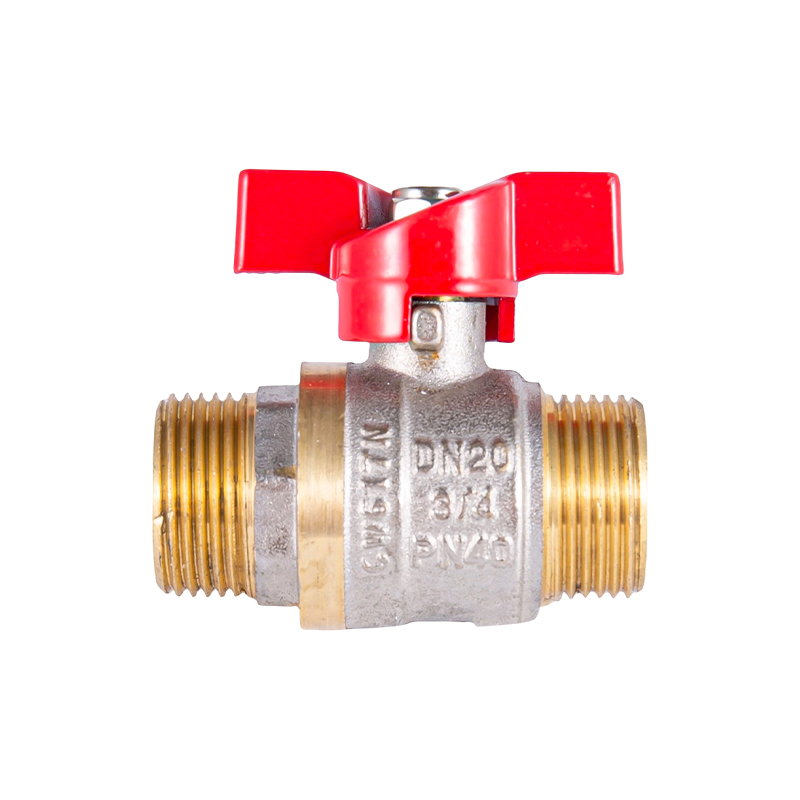

Our household brass ball valve has a nominal pressure of 1.6 MPa.

Working medium: water, noncorrosive liquid, saturated vapor

Working temperature: -10 ℃ ≤ t ≤ 120 ℃ Specification: 1/2" to 4"; pipe thread meets ISO228 standard.

The surface of the product can be natural color, nickel-plated, or chrome-plated, and the valve body can be made of different copper materials, such as HPB57-3, CW617, CW617N, C3700, etc. The other parts can be made of copper, iron, stainless steel, or zinc alloy, fully meeting the needs of all market customers for products at different price points.

Brass ball valves are widely used components in fluid control systems, offering a dependable way to start or stop the flow of liquids and gases. Known for their robust construction and versatility, these valves are applied across many industries, including plumbing, heating, irrigation, and industrial equipment.

The basic working principle of a brass ball valve involves a hollow, perforated ball that rotates within the valve body to allow or block flow. When the handle is turned 90 degrees, the internal ball aligns with the flow path, enabling or stopping the movement of fluid. This simple yet effective mechanism helps reduce wear and promotes consistent performance over time.

One of the reasons brass is selected as a primary material for these valves is its resistance to corrosion and ease of machining. Brass also provides good durability, which makes it suitable for both indoor and outdoor systems, including potable water lines, oil pipelines, and air compressor setups. The metal's balance of strength and malleability allows for reliable sealing and reduced leakage when paired with suitable seals or threads.

In terms of maintenance, brass ball valves are relatively low in upkeep requirements. The quarter-turn operation limits mechanical friction, and the internal components are typically resistant to scale buildup. When necessary, the valve can be disassembled for inspection or part replacement, depending on the design.

Overall, this category includes a broad selection of brass ball valves designed to meet various project requirements. Whether for residential plumbing upgrades or industrial flow control setups, customers can select from numerous specifications to find the right match for their system. Each valve type offers specific features suited to flow capacity, pressure tolerance, and installation environment.

The company is adjacent to the seaport city of Wenzhou Airport in the south, Jiaojiao, Taizhou and Wenzhou Expressways in the west. It is an hour and a half away from Wenzhou and Taizhou Airports, and the transportation is extremely convenient. The company mainly produces copper ball valves, copper globe valves, copper check valves, copper pressure reducing valves, temperature control valves, angle valves and other copper valve products with complete specifications and guaranteed quality. In the fiercely competitive market economy environment, Xianyun Valve adheres to the development concept of "quality determines strength", adheres to the business policy of "people-oriented, honesty as the criterion", insists on relying on technological innovation, constantly absorbs advanced experience at home and abroad, and comprehensively promotes advanced Yun Valve has transformed from a traditional enterprise to a high-tech industry.

The company now has advanced production and testing equipment and can independently design, develop and produce hundreds of products. The company pays special attention to brand image, constantly develops new products and improves product quality, and develops the market with the best products. "Excellent quality, customer satisfaction" is the company's eternal pursuit. The company will be guided by market demand, continue to innovate, and wholeheartedly provide users with high-quality products and perfect after-sales services.

The company pays attention to the training of talents, strives to build a "first luck spirit" of hard work, unity and hard work, and strives to build a "strength enterprise".

English

English 中文简体

中文简体 русский

русский Email us now!

Email us now!